The wooden beehive parts are called woodware. A Langstroth hive is very simple to make. The hives use rabbet joints which are interlocking wood joints that make the box strong and stable. If you are have the right stuff you can make dovetail joints. If, like me, you just aren’t good at carpentry, you can just use screws and butt joints, which are probably just fine.

The wooden beehive parts are called woodware. A Langstroth hive is very simple to make. The hives use rabbet joints which are interlocking wood joints that make the box strong and stable. If you are have the right stuff you can make dovetail joints. If, like me, you just aren’t good at carpentry, you can just use screws and butt joints, which are probably just fine.

A precut and unassembled hive with an assembled bottom board, divider board and telescoping top covered with stainless steel, costs about $60 at most of the online shops. It weighs 57 pounds and shipping is about $25. This includes frames.

Making your own hive costs about $30-$40 worth of lumber and two or three hours of time.

It’s the time that gets you. You have to drive to the lumber yard and get an 8 foot length of 1x12x8 shelving that is relatively free of bad knots. You need a half sheet of 3/4 inch sheathing (5/8 will do just fine), and a half sheet of 1/4 inch plywood. You need as piece of sheet metal, or sanded tar paper for the cover to keep the rain off. The trip will kill an hour and cost something for gas.

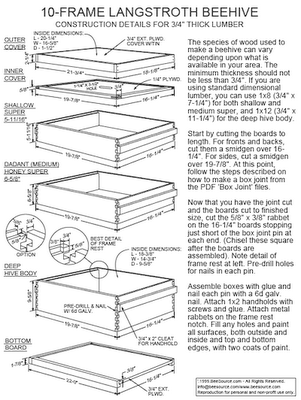

You need to rip the lumber down to 9-5/8 (and probably go back to the lumber store when you screw it up). You need to chop the sides and then cut the rabbets. You have to cut the top and bottom sidepieces and the plywood parts. You need either a dado blade on a table saw or a router to cut the grooves in the bottom and top sidepieces and the shelf for the frames.

You need to assemble and glue the top and bottom. You need to cut and attach the sheet metal to the top.

All this should take more than an hour to set up and get right. To be safe I am saying that it takes two hours with restarts and beer breaks.

Pay yourself $7 an hour and add about $20 to the cost of the project. You are probably worth more than this, but I am paying you MacDonald’s wages for even thinking that this is going to come out well.

The hive kits include the unassembled frames. You have to pay about $15 to get these shipped to your house, and you have to buy the foundation anyway.

Let’s total it up:

$35 in lumber + $20 labor + $15 frames =Total $70

If you bought the unassembled kit for $60 plus $25 shipping, you’d pay $85.

So you saved about $15, more or less.

You also spent 3 hours on a Saturday morning risking your fingers on the table saw and producing a product inferior to the mass produced ones. You could have been out at a game, or sleeping late, or having a good time doing almost anything else.

If you are still interested, www.Beesource.com has Hive Plans.